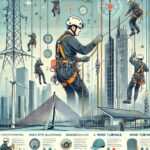

Rope access has emerged as a crucial technique for working at height, offering a safe and efficient alternative to traditional methods such as scaffolding and aerial lifts. This technique relies on the use of ropes and harnesses, allowing trained technicians to access hard-to-reach areas with minimal disruption. The importance of rope access extends across multiple industries, including construction, maintenance, telecommunications, and renewable energy, where the ability to perform tasks safely and efficiently is paramount.

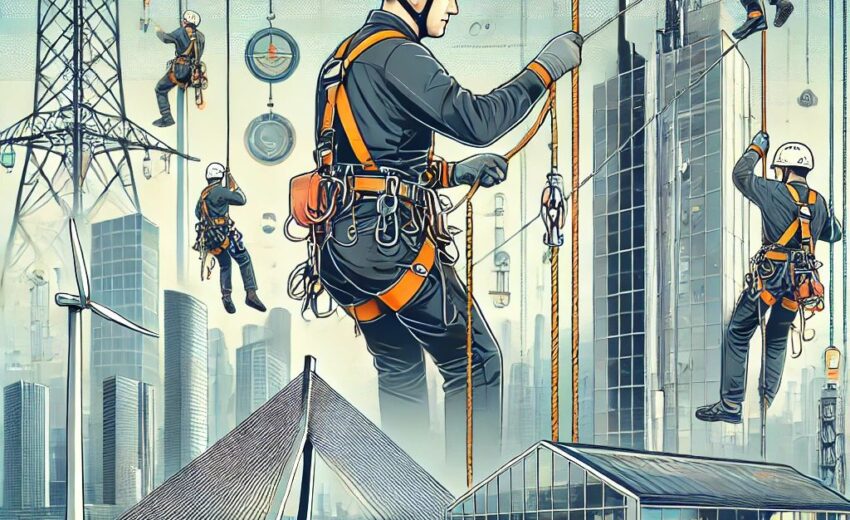

One of the biggest advantages of rope access is its strong emphasis on safety. The system is designed with a dual-rope mechanism, ensuring that technicians have a primary working rope and a secondary safety rope. This redundancy minimizes the risk of accidents, making it one of the safest work-at-height solutions available. Technicians undergo extensive training and certification processes to master the necessary skills, with organizations like IRATA and SPRAT setting global standards for competence and safety.

Cost-effectiveness is another reason why many industries prefer rope access over conventional alternatives. Scaffolding and aerial platforms require significant time, labor, and material costs for setup and dismantling. In contrast, rope access minimizes these expenses by reducing the need for heavy equipment and large workforces. Additionally, its flexibility enables technicians to complete tasks quickly, reducing downtime and increasing overall efficiency.

Rope access is also highly versatile, making it suitable for a variety of tasks. It is widely used in building maintenance, allowing workers to clean windows, repair facades, and inspect structures with ease. In the oil and gas sector, it is indispensable for offshore rig maintenance and pipeline inspections. Telecommunications companies rely on rope access for tower climbing and antenna installation, while the renewable energy industry depends on it for wind turbine maintenance and inspection.

A key benefit of rope access is its minimal environmental impact. Unlike fuel-powered machinery and extensive scaffolding structures, rope access requires fewer resources and leaves a smaller footprint. This makes it an environmentally sustainable choice, aligning with global efforts to reduce emissions and energy consumption in industrial activities.

With its emphasis on safety, cost-effectiveness, versatility, and sustainability, rope access continues to be a preferred choice for industries requiring work at height. As technology and training standards continue to advance, this method will remain an indispensable tool for ensuring safe, efficient, and eco-friendly operations in various sectors.